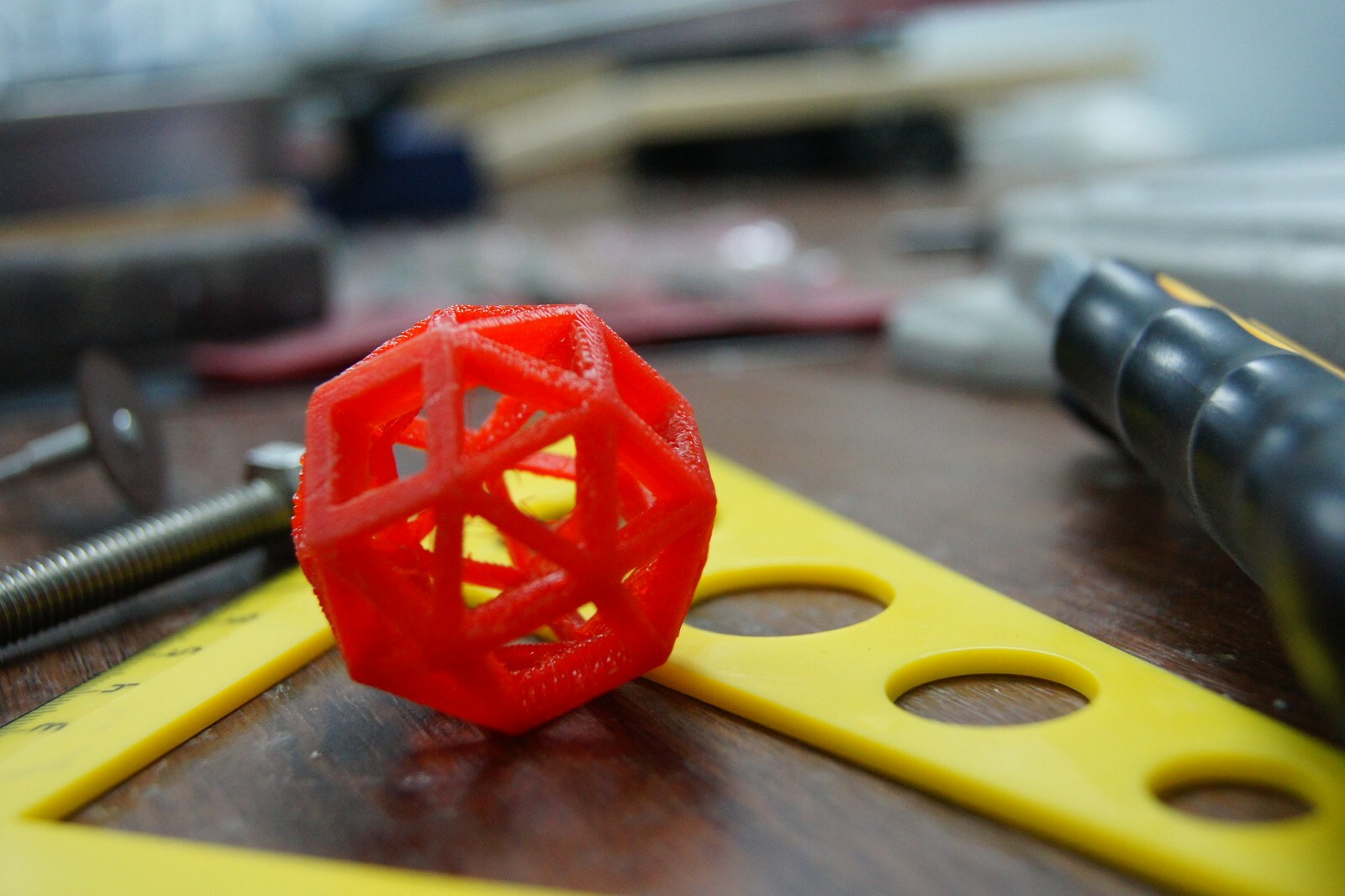

3D Printer Filament Types

With so many different types of filament available out there, how are you supposed to know which one to buy? The answer depends on what you want to print and what the printed object will be used for. In today's 3D printing craze, the popularity of 3D printing keeps growing and growing. New types of filament are being created and even hybrid plastic filaments are being made. Here are some of the most common and a few of the uncommon filament types available today.

ABS

ABS (Acrylonitrile Butadiene Styrene) filament is one of the most popular 3D printing materials, the other being PLA. In a comparison versus PLA, ABS filament is more flexible and more impact resistant; ABS also boasts a higher melt point and a longer life span. ABS is used in many of our every day lives in products ranging from car parts to luggage and even toys. Our favorite childhood toy, Legos, is made out of ABS. Acetone is used to weld two printed ABS filament parts together since ABS is soluble in acetone. The printed parts from ABS filament have a matte finish to them, but a simple brushing of acetone over the printed ABS plastic part will leave a high gloss look. ABS filament requires a heated build platform to minimize warping during printing and adheres well to Kapton tape.

ABS (Acrylonitrile Butadiene Styrene) filament is one of the most popular 3D printing materials, the other being PLA. In a comparison versus PLA, ABS filament is more flexible and more impact resistant; ABS also boasts a higher melt point and a longer life span. ABS is used in many of our every day lives in products ranging from car parts to luggage and even toys. Our favorite childhood toy, Legos, is made out of ABS. Acetone is used to weld two printed ABS filament parts together since ABS is soluble in acetone. The printed parts from ABS filament have a matte finish to them, but a simple brushing of acetone over the printed ABS plastic part will leave a high gloss look. ABS filament requires a heated build platform to minimize warping during printing and adheres well to Kapton tape.

PLA

PLA (Polylactic Acid) filament is the other popular 3D printing filament with ABS filament. PLA filament is heralded because of its ease of use. The extruding temperature required to print is lower than ABS filament. Also, the filament does not suffer from warping as much as other filaments, so a heated build platform is not required. PLA filament adheres well to blue painter's tape. Users can expect to print high detail PLA objects that contain sharp crisp edges. PLA prints tend to have a glossier look without any post processing. PLA is viewed as an eco-friendly material because it is derived from corn and is compostable.

HIPS

HIPS (High Impact Polystyrene) filament can be used for general 3D printing, but HIPS filament exploded on to the 3D printing market because of its ability to dissolve in Limonene, a citrus-scented solvent. HIPS and ABS share similar printing characteristics such as printing temperature, and therefore, they adhere well to each other. Printed objects made using HIPS filament as a support can be easily broken off with any remaining HIPS simply dissolving away in Limonene. Complicated and previously unprintable objects containing interior support structures are now possible with HIPS filament.

PVA

PVA (Polyvinyl Alcohol) filament is another dissolvable filament. PVA is primarily used as a support structure, and it completely dissolves in water. PVA filament was really the first dissolvable 3D material that opened the doors to soluble prints. The types of products that can be printed with PVA filament range from simple science demonstrations to biotechnological applications. PVA filament can be printed on most standard FFF 3D printers and adheres well to blue painter's tape.

PVA (Polyvinyl Alcohol) filament is another dissolvable filament. PVA is primarily used as a support structure, and it completely dissolves in water. PVA filament was really the first dissolvable 3D material that opened the doors to soluble prints. The types of products that can be printed with PVA filament range from simple science demonstrations to biotechnological applications. PVA filament can be printed on most standard FFF 3D printers and adheres well to blue painter's tape.

Wood

Wood filament is a revolutionary 3D printing material. The filament contains recycled wood as well as binding polymers. The Gizmo Dorks Wood filament prints very similar to PLA print temperatures and also does not warp very much. The unique feature about Wood filament is that a printed object looks, feels, and smells like wood. Even printing at higher temperatures will cause the wood to darken, so varying the print temperatures will give the object a light / dark effect. The wood filament print can also be post processed by cutting, sanding, grinding, or painting. The different possible prints available to Wood filament are endless!

Wood filament is a revolutionary 3D printing material. The filament contains recycled wood as well as binding polymers. The Gizmo Dorks Wood filament prints very similar to PLA print temperatures and also does not warp very much. The unique feature about Wood filament is that a printed object looks, feels, and smells like wood. Even printing at higher temperatures will cause the wood to darken, so varying the print temperatures will give the object a light / dark effect. The wood filament print can also be post processed by cutting, sanding, grinding, or painting. The different possible prints available to Wood filament are endless!

Nylon

Nylon filament has become a popular alternative choice as a 3D printing material. Nylon offers high flexibility and great strength while being extremely light weight. Printed Nylon parts are not as brittle as those printed with either ABS or PLA, which means printed parts can be ten times stronger without cracking or breaking. Nylon filament is a great choice for printing a wide variety of objects such as gears or phone cases to prosthetic models. Nylon also doesn't crack or delaminate compared to ABS, so printing parts that need to be threaded without cracking are easy. Nylon does have a tendency to absorb a lot of moisture, so baking Nylon filament in the oven prior to use is recommended.

Nylon filament has become a popular alternative choice as a 3D printing material. Nylon offers high flexibility and great strength while being extremely light weight. Printed Nylon parts are not as brittle as those printed with either ABS or PLA, which means printed parts can be ten times stronger without cracking or breaking. Nylon filament is a great choice for printing a wide variety of objects such as gears or phone cases to prosthetic models. Nylon also doesn't crack or delaminate compared to ABS, so printing parts that need to be threaded without cracking are easy. Nylon does have a tendency to absorb a lot of moisture, so baking Nylon filament in the oven prior to use is recommended.

PETG

PETG (Polyethylene Terephthalate Glycol-modified) filament is an upgraded version of the popular PET filament. The difference between PET and PETG is the addition of glycol to PETG, which prevents crystallization and makes the filament less brittle. For PETG filament, impact resistance is its shining characteristic; it also has very high optical clarity. Compared to Acetal and Nylon, PETG filament has better resistance to acidic conditions and higher wear and abrasion resistance. PETG has many uses and applications because of it's excellent chemical properties; the plastic can be found in products ranging from medical equipment, food packaging, signage, and more.

PETG (Polyethylene Terephthalate Glycol-modified) filament is an upgraded version of the popular PET filament. The difference between PET and PETG is the addition of glycol to PETG, which prevents crystallization and makes the filament less brittle. For PETG filament, impact resistance is its shining characteristic; it also has very high optical clarity. Compared to Acetal and Nylon, PETG filament has better resistance to acidic conditions and higher wear and abrasion resistance. PETG has many uses and applications because of it's excellent chemical properties; the plastic can be found in products ranging from medical equipment, food packaging, signage, and more.

Acetal

Acetal (Polyoxymethylene abbreviated POM) filament is an ideal thermoplastic that is strong and rigid with excellent wear resistance. One warning when printing with Acetal filament is at too high of a temperature Acetal degrades to Formaldehyde. Acetal filament requires a heated bed to print because of warping. Blue tape with hairspray or a wooden platform (birch ply or high density cardboard) can be used as build platforms. Acetal filament has very low friction, so it is used to print objects such as gears, bearings, moving parts, etc.

Polycarbonate

Polycarbonate filament is a very hard and impact resistant thermoplastic; it is the best in terms of impact resistant of all thermoplastics that can be 3D printed. Polycarbonate filament is also temperature resistant and has an interesting ability to be bent cold. Polycarbonate blocks UV light while also being very optically clear, and so is commonly used in protective eye wear such as sunglasses or goggles. However, it is not easy to keep Polycarbonate filament clear during extrusion. Polycarbonate is used in a wide variety of applications such as bullet-proof glass, DVDs, smartphones, etc.

Polycarbonate filament is a very hard and impact resistant thermoplastic; it is the best in terms of impact resistant of all thermoplastics that can be 3D printed. Polycarbonate filament is also temperature resistant and has an interesting ability to be bent cold. Polycarbonate blocks UV light while also being very optically clear, and so is commonly used in protective eye wear such as sunglasses or goggles. However, it is not easy to keep Polycarbonate filament clear during extrusion. Polycarbonate is used in a wide variety of applications such as bullet-proof glass, DVDs, smartphones, etc.

Polypropylene

Polypropylene filament is tough and flexible; the filament strength is about on par with that of ABS filament. Polypropylene is a semi-crystalline thermoplastic, and it is normally used in various products such as food safe containers. Although Polypropylene might be FDA safe for food, the inherent processes of extrusion in 3D printing have not been approved. Polypropylene has a higher impact strength and elongation than PLA. However, it has a lower flexural modulus and flexural strength. The filament has a decent temperature resistance, and so it is commonly used in laboratory plastics to withstand the heat in an autoclave. Polypropylene also has many other functions and can be found in everyday objects like chairs, clothing, rope, toys, and more. Polypropylene is also recyclable and has the number 5 for its resin identification code.